Monocrystalline and polycrystalline are two popular options of solar panels available on the market today. Both solar panels produce energy from the sun, and for the most part, they’re made from pretty much the same materials.

So, which option should you choose between these two when you’re shopping? These solar panels have some key differences that you should know when making a purchase decision.

In this article, you’re going to understand the critical differences between monocrystalline and polycrystalline solar panels.

Please read this until the end if you’re looking to install a solar panel system that will match your needs!

Monocrystalline vs. Polycrystalline: How Are They Made?

How Is a Mono Solar Panel Made?

Monocrystalline solar panels are premium solar products made of silicon, otherwise known as Si02, Silica, or Quartzite. The two popular models of monocrystalline solar panels are LG monocrystalline panels and SunPower monocrystalline panels.

To make solar cells for monocrystalline solar panels, the manufacturers put SiO2 and Carbon in special ovens and melt them at temperatures above 2,552 degrees Fahrenheit. This leaves behind 98-99.99% pure silicon.

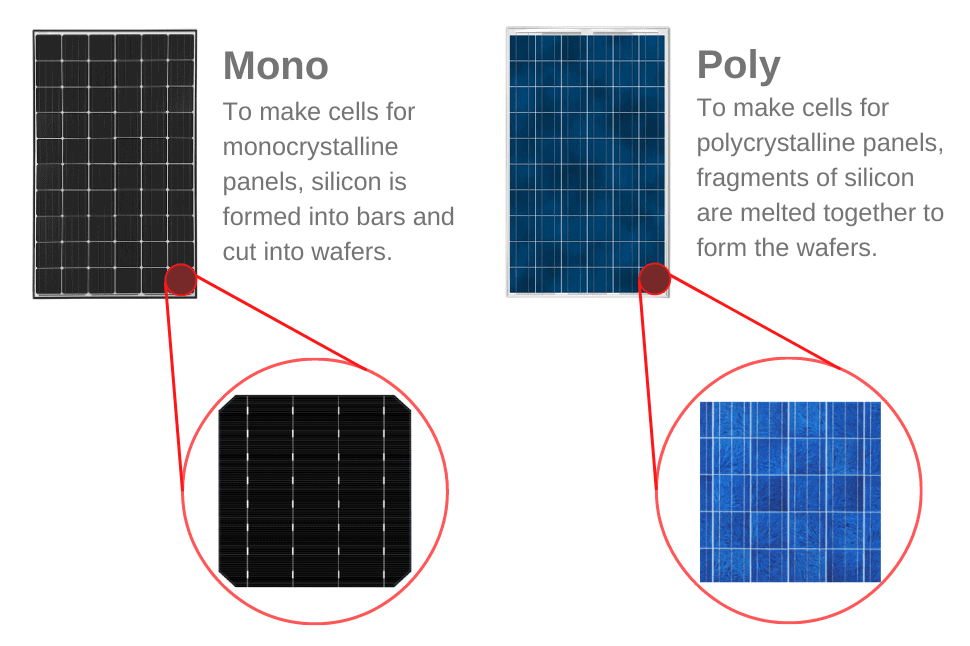

The term “monocrystalline” means that the solar cell is comprised of single-crystal silicon. Every individual cell has a silicon wafer that’s produced out of a single crystal of silicon.

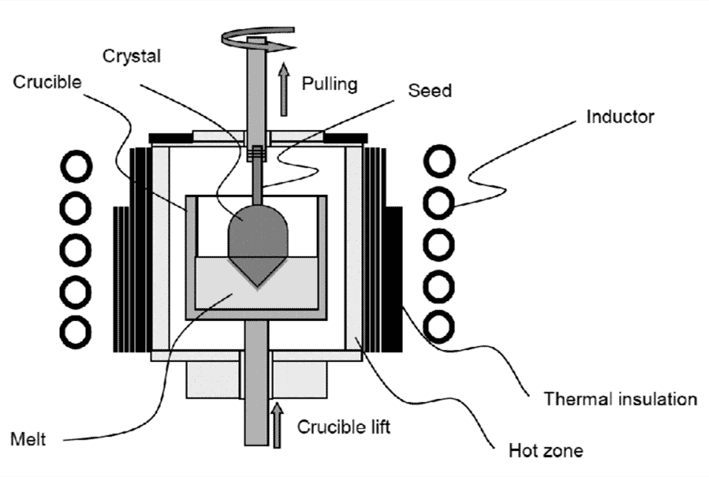

Monocrystalline solar panel manufacturers form the single crystal using the Czochralski method. This is where they place a seed crystal into a vat of pure molten silicon at very high temperatures.

They then draw the seed up and let the molten silicon form around it to create one large crystal. This large crystal is what is sometimes known as an ingot. The manufacturers cut the ingot into thin wafers and use it to make the solar cells.

Using a single crystal provides electrons with more space to move. This, in turn, allows for a better electricity flow.

How Is a Poly Solar Panel Made?

Much like monocrystalline, polycrystalline solar panels, also known as multi-crystalline or many-crystalline solar panels, are also made from silicon.

However, the manufacturers here do not pull the single pure ingot to form a homogenous cylindrical crystal using the Czochralski Process.

Instead, they combine many silicon fragments and melt them by using the casting method. The melted silicon fragments are poured into cubic-shaped growth crucibles and left to cool.

Once the molten silicon has cooled and solidified, the manufacturers cut the ingots, polish, improve, and assemble them to form wafers for the panels.

The crystal surrounding the seed in the polycrystalline solar panel is not uniform. It tends to branch into several smaller crystals, thus the name “polycrystalline.”

Because each cell has many crystals, there’s not much freedom for the electrons to move. This means that the flow of electricity isn’t that good.

Even so, the process of combining, molding, and treating smaller silicon bits to create the solar cell is less wasteful. This is because no raw materials are disposed of during manufacturing.

Polycrystalline solar panels are an ideal option if you’re looking to install your solar panel on a budget. The Amerisolar products are excellent examples of polycrystalline solar panels.

Monocrystalline vs. Polycrystalline: What Do They Look Like?

What Does a Mono Solar Panel Look Like?

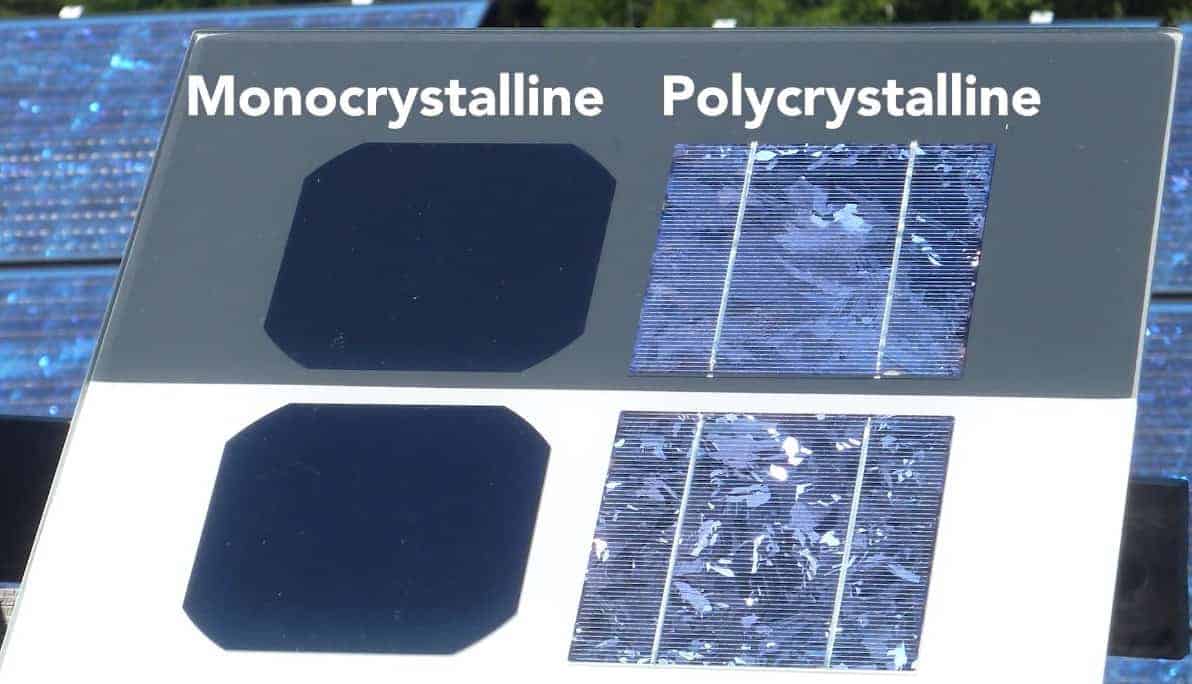

Pure silicon typically has a rounded shape. Therefore, it produces square wafers with rounded edges when cut. These rounded edges form tiny gaps between the cells when assembled.

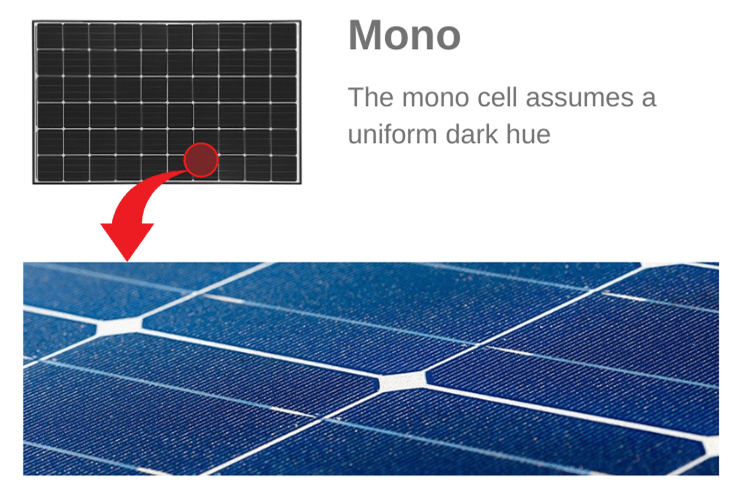

Because a monocrystalline solar panel is made from pure silicon, it will assume a uniform dark hue. This dark color will often result from the interaction between light and pure silicon.

So, if you happen to see a solar panel with a uniform dark appearance and small spaces between each cell, it should be a monocrystalline solar panel.

Usually, a monocrystalline solar panel will have either 60 or 72 solar cells depending on how big the panel is. Mono silicon panels for residential installations will usually contain 60 cells.

Oh sorry! The monocrystalline solar cell’s dark hue may fool you into believing there are limited colors and designs available.

The truth is that there are multiple colors for the back sheets and designs for the frames. As such, you can easily find an option that meets your personal preferences.

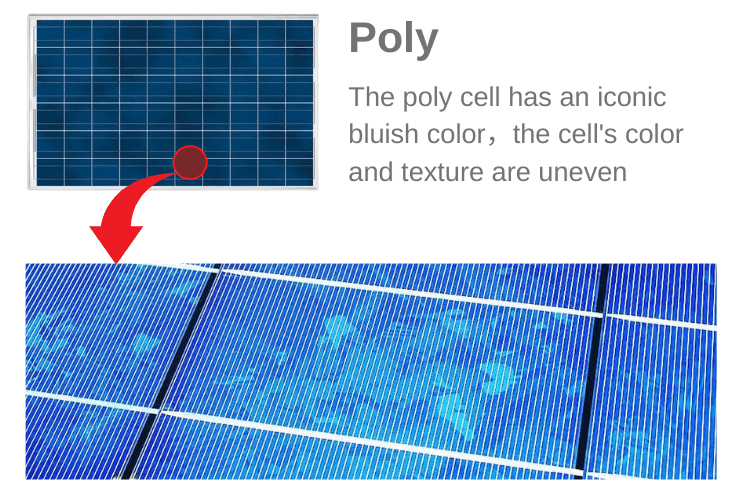

What Does a Poly Solar Panel Look Like?

Unlike the mono solar cell’s uniform dark look, the poly cell has an iconic bluish color. This panel is manufactured in a way that causes it to take a bluish hue when it interacts with sunlight.

By blending several silicon fragments, poly solar panels get their iconic blue hue. If you look at these panels closely, you’ll realize that the cell’s color and texture are uneven.

Furthermore, these panels do not have any rounded edges, and so you won’t see any large white spaces on the panel. This is because manufacturers don’t cut polycrystalline wafers from cylinders like they do with the monocrystalline panels.

Just like the monocrystalline panels, the polycrystalline panels may have either 60 or 72 cells. The number of cells also varies according to the panel’s size, with most residential options containing 60 cells.

Some people consider the polycrystalline panel’s bluish color to be an eyesore. However, it is important to know that polycrystalline cells can have plenty of frame designs and colorful back sheets to suit your roof.

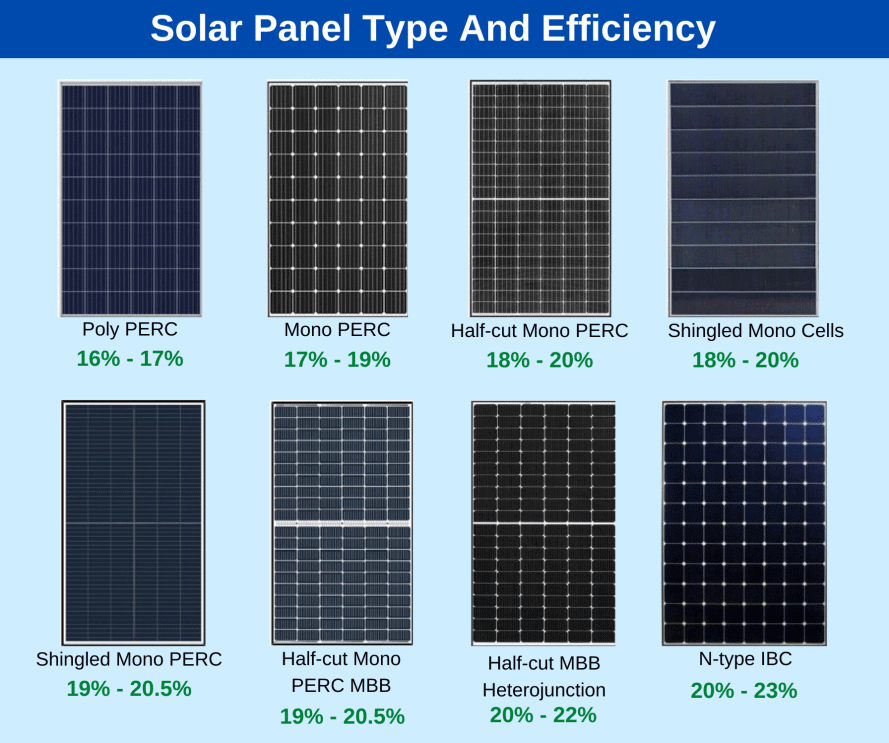

Monocrystalline vs. Polycrystalline Solar Panels: Efficiency

How Efficient Is a Mono Solar Panel?

The solar panel’s efficiency rating is a measure of how good the cell is at converting energy from the sun into electricity. The more efficient the solar cell is, the less installation space it requires.

Monocrystalline cells typically have the highest efficiency of all types of solar panels. Their efficiency rating can range from 15-20% or even higher, making them your best bet if your PV system is limited by the amount of space on your roof.

Mono cells have the highest efficiency and power capacity because they’re made from single-crystal silicon. As a result, electrons get ample space to move quickly through the cell to improve electricity flow.

Monocrystalline solar cells produce more power per square foot than polycrystalline cells, so they’re very space-efficient.

Additionally, they post better performance even in low light conditions. These panels also tend to be more effective in warm weather conditions.

How Efficient Is a Poly Solar Panel?

Polycrystalline solar panels aren’t that impressive as far efficiency rating is concerned. Like I mentioned earlier, the polycrystalline structure is made of too many crystals. Therefore, electrons have less room to enable them to move with ease.

The high resistance in the movement of the electrons coupled with low silicon purity makes them less efficient in electricity generation.

Most polycrystalline PV cells boast about a 13-16% efficiency rating. As expected, these may not make sense if you have limited space on your roof.

The good thing about polycrystalline solar panels is that they are a more economical option. So if you’re on a budget and have a lot of space on your roof, lower-efficiency polycrystalline will suffice your needs.

Monocrystalline vs. Polycrystalline Solar Panels: Temperature Coefficient

What Is the Effect of Temperature on Mono Solar Panels Efficiency?

The temperature coefficient measures how much the power output drops when the panel heat rises above 25 degrees Celsius or 77 degrees Fahrenheit. You need to know that solar panels don’t like heat but like light.

Manufacturers often indicate the solar panel’s temperature coefficient spec in their product labels. Monocrystalline solar panels have a lower temperature coefficient rated at around -0.3%/C to -0.5%/C.

That means if the temperature rises by 1 degree Celsius or 1.8 degrees Fahrenheit, the solar cell will momentarily lose between 0.3% and 0.5% of its efficiency.

Because of their temperature coefficient figures, monocrystalline solar panels will deliver higher efficiency in warm weather conditions.

So if you live in a region experiencing longer and warmer summers, you should be careful about your solar panel’s temperature coefficient.

What Is the Effect of Temperature on Poly Solar Panels?

Polycrystalline solar panels have a higher temperature coefficient compared to monocrystalline ones.

Generally, solar panels based on polycrystalline solar cells have a temperature coefficient in the -0.3% to -1% range.

Accordingly, these solar panels tend to lose more of their efficiency temporarily should the temperature rise.

This means that polycrystalline solar panels may not deliver optimal performance in high-temperature areas.

Monocrystalline vs. Polycrystalline Solar Panels: Degradation Rate

How Long Does a Mono Solar Panel Last?

The degradation rate shows the solar cell’s expected lifespan or the annual energy production loss.

Solar panels normally have a 0.3% to 1% degradation rate, meaning that their total power output will drop by 0.3% to 1% every year.

The annual efficiency loss for most monocrystalline PV panels stands at around 0.3% to 0.8%.

Let’s put it in context for a better understanding: suppose your monocrystalline solar panel has a 0.5% degradation rate.

In this case, the system will operate at 95% efficiency in 10 years, 90% efficiency in 20 years, and so on until it becomes completely inefficient.

You can expect your monocrystalline solar panel to last for 40 years or more depending on several factors. Also, mono solar panels are backed by 25 or 30-year warranties.

How Long Does a Poly Solar Panel Last?

The degradation rate for polycrystalline solar panels is higher than that of monocrystalline solar panels. As such, they will lose their efficiency at a faster rate.

But that doesn’t mean they don’t last. A good poly solar panel can last for up to 20-35 years and even more.

Monocrystalline vs. Polycrystalline Solar Panels: Cost Comparison

What is the Cost of a Mono Solar Panel?

There are tons of advantages that come with monocrystalline solar panels. However, they don’t come cheap as they have a high initial cost.

Monocrystalline solar panels are the most expensive types of PV solar panels to produce. Their manufacturing process is highly energy-intensive and results in silicon waste.

What is the Cost of a Poly Solar Panel?

Polycrystalline solar panels are relatively cheaper than their monocrystalline solar panel equivalents. They also have less cost per watt relative to their efficiency.

The reason for the lower cost of polycrystalline solar panels is their manufacturing process. Ideally, the process utilizes less energy and creates less silicon waste, translating to lower production costs.

Monocrystalline vs. Polycrystalline Solar Panels: Which Is Better?

|

Monocrystalline |

Polycrystalline |

|

|

Efficiency |

High |

Low |

|

Cost |

High |

Low |

|

Solar cells color |

Black hue |

Bluish hue |

|

Lifespan |

Minimum 25 years |

Up to 25 years |

|

Temperature coeff |

High |

Low |

|

Major manufacturers |

Sunpower, LG, Hyundai |

Trina, SolarWorld, Hanwha |

Whether to choose monocrystalline or polycrystalline solar panels will eventually boil down to your unique needs.

If money is not a problem and you want the best of both worlds of efficiency and aesthetics, you’re better off with monocrystalline panels.

However, if you’re on a shoestring budget and have limited installation space on your roof, polycrystalline panels would make the most sense.